Haite Systems is your partner throughout the complete project:

starting from the conceptual design,

on through detailed engineering, procurement and manufacturing, up until installation and commissioning, and if required training and maintenance.

Every project is different. Thanks to highly qualified and experienced in-house engineers,

we are able to support you during every project stage, anywhere in the world.

● Determine the purpose of stirring, perform liquid mixing, solid liquid suspension, gas or liquid or liquid dispersion, whether it is necessary to achieve process purposes such as heat transfer, absorption, extraction, dissolving crystals;

● The stirring tank can be selected according to the characteristics of the process;

● Equipment is made of stainless steel, beautiful and beautiful, complete;

● The equipment structure design is reasonable, advanced, durable, and has the characteristics of simple operation and convenient use;

The strong ventilation speed frozen device uses a wing tube evaporator, and the air supply manpower adopts a high -pressure centrifugal fan with a high head. It has the characteristics of high heat transfer efficiency and small area. Generally, this device, the speed of the air is 3 to 6m/s when the frozen material is being frozen, and the temperature is - 40 to - 30 ° C. Therefore, its quick -frozen speed is 2 to 4 times faster than the rack speed frozen speed. You can use mechanical interruption or continuous in and out, with a large production capacity.

● Made of high -quality stainless steel materials, beautiful and practical, clean and hygienic, meet food hygiene standards;

● Select the electrical components of famous factories, automatically enter, automatic gas removal protection and steam pressure gauge display;

● Adopt patented design high -efficiency and gradual door lock hinges, open, easy to turn off;

According to the customer's process requirements, customized the baking plan compatible with each product.

Operating principle

The flour is mixed with cold air in an intermediate hopper located in between the flour silos and the flour dispensing station.

The cold air is generated by a heat exchanger and continuously circulates in the bin via a high pressure fan and a fluidizing bed.

The air is perfectly homogenized with the flour to give a uniform temperature.

A temperature probe monitors the temperature of the flour and control the heat exchanger till the set point of the temperature.

Advantages

Avoids manual addition of ice

Low operating cost (no CO2)

Gentle heat treatment

Consistent temperature batch after batch

Uniform temperature of teh flour

Friendly to environment (no C02)

Blending (powders with powders) and mixing (liquids with powders, liquids with liquids) is a frequent activity in the solid and liquid business.

The batch size, the cleanability of the mixer, the energy needed to create a homogeneous mix, continuous or batch … these and other parameters determine which mixer best suits a particular application. We select the right blender or mixer based on your product expertise and our know-how in the existing technologies, tested in our lab, to guarantee the best solution.

A production process is made up of different steps, most of which are physically separate from each other. The intermediate products have to be transferred with minimum degradation. We have vast experience in common solutions such as mechanical transport (screws, vibratory trays, conveyor belts, AGVs etc.) as well as pneumatic transport for solids and pumps for liquids.

In fact Haite systems is a technology leader in this field, with well-equipped test facilities and capabilities in over/under-pressure systems, both in dense and in dilute phase.

Continuous or batch, volumetric or gravimetric, loss-in-weight or gain-in-weight … accurate dosing for recipe preparation or control weighing for stock management all require different weighing systems.

Haite systems is able to guarantee optimal design of the weighing and dosing concept, thanks to its specific expertise in dosing and weighing and its test facilities for trials with liquids or solids.

According to the customer's process requirements, customize the storage and transportation of each raw material.

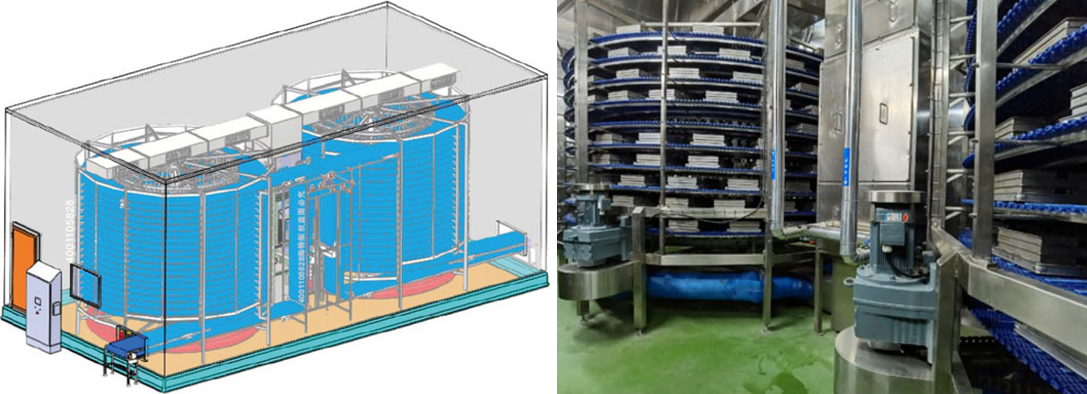

Spiral cooling tower

● Spiral tubes that can later be converted into refrigerated cooling towers or freezers

● Choose American Interloc plastic mesh belt

● 9 million ultra-high molecular weight wear-resistant strips were selected

● Strong and durable construction

● The overall production technology is excellent

● The structure is easy to clean and hygienic

● Durable, easy to maintain and easy to clean

● A spiral tower that can later be converted into a freezer or freezer room

Continuous vertical cooling tower with disk

● The stepped in-line tray cooling tower is used to cool the baking tray after the baking process

● The product is cooled on the tray and then enters the dishing system

● The stepped cooling system allows you to take full advantage of the available height of the building

● Step coolers are suitable for high and low volume production lines and different types of baking

● Continuous cooling tower can be designed

● The product carrier moves on the plastic plate

Middle seed awakening system

● Sanitary design curb system, on-site welding, filled concrete;

● Central constant temperature and humidity system;

● Water spray humidification, without heat to provide humidity;

● First in first out layout, a variety of ways to enter and exit the room;

● There are a variety of styles to choose from, from semi-automatic to fully automatic, AGV systems, two-course bread systems and three-course bread systems.

Final wake up system

● Provides an automated and versatile wake-up environment with a large number of outputs

● Central constant temperature and humidity system

● The baking tray wake-up system easily ADAPTS to changes in pan size

● Usually designed with flat doors, automatic doors can also be selected

● Suitable for factories that produce different products in small batches as well as continuously produce large batches of products.

● Dough waxing also benefits from the ability to use space more efficiently than other types of waxing.

Automatic wake up system

● Provides an automated and versatile wake-up environment with a large number of outputs

● Central constant temperature and humidity system

● Baking tray wake can easily adapt to changes in stripper size,

● Integrated shelf loading/shelf unloading, it can be designed as part of a fully automated production line.

● The proofing time of each channel can be set, and the door automatically opens/closes

● Suitable for factories producing small batches of different products as well as large batches of continuous products.

Spiral wake tower

● Complete system including all controls and accessory conveyors

● Modular construction, easy to install

● Process standards keep heat and humidity within 1 degree Celsius

● Various belts, including modular plastic, are lightweight and non-stick

● Better quality products compared to the tier car wake up

● Eliminate clogged product transfers

● Product positioning control to eliminate chucks

● Smaller footprint than other products

● Applicable product on the belt directly wake hair